In today’s fast-paced business environment, manufacturers are facing a major shift in customer expectations, driven by the rise of millennials and younger generations as key decision-makers. According to a recent Salesforce report, nearly one-third of manufacturing customers now fall into this demographic, and they expect the same level of convenience, transparency, and real-time access they experience with consumer brands like Amazon. For manufacturers, meeting these demands is no longer optional—it’s essential to remain competitive. By embracing digital solutions that streamline order tracking, provide instant access to invoices, and reduce friction in customer interactions, manufacturers can build trust and strengthen relationships. Is your business ready to meet these evolving expectations? Explore how our expertise can help you stay ahead of the curve and deliver the seamless experience your customers demand.

Change in Customer Expectations

Manufacturers are learning that their customer base is evolving. According to the Saleforce report Creating a New Future: How Digital Transformation will Remake Customer Expectation in the Manufacturing Industry, “close to one-third of their customer are now millennials or younger.” We live in a world where in our personal lives, we are able to quickly see and understand where our orders are. When you buy something off of Amazon, they are able to tell you when it’s been picked from the warehouse, and when it will arrive. You also have access to your invoice so you can reconcile what you’ve spent. When customers have to call the manufacturer’s Sales or Customer Service teams to get updates, it creates friction. Customers now expect the same level of service they receive from their consumer brands in the B2B world.

Manufacturing Companies Data Challenge

The first challenge is that manufacturers use many different systems to manage their customer data. Order, invoice, shipping, and accounting information is usually set up in an Enterprise Resource Planning System (ERP), and sales & marketing information is managed out of a Customer Relationship Management system. When these systems are disconnected, it makes it difficult to share the information customers are searching for with them directly.

The second challenge is the amount of data Manufacturer’s collect. According to The National Association of Manufacturers (NAM) recent report “Manufacturing in 2030: The Opportunity and Challenge of Manufacturing Data”, it stated that:

How data is used: As manufacturers advance along their journey, data is becoming their lifeblood, driving insights and decision-making. Yet the survey revealed a gap between available data sources and their utilization, a notable area for improvement as the industry looks toward the future.

- Spreadsheets are still king: 70% of manufacturers enter data to them manually, and 68% still use them to analyze data.

- 44% of manufacturing leaders say the amount of data they collect is double what it was two years ago, and they anticipate it will triple by 2030.

- While nearly 60% of manufacturers use data to understand and optimize projects, there is a shift toward using data to make predictions about operational performance, including machine performance, in the next decade.

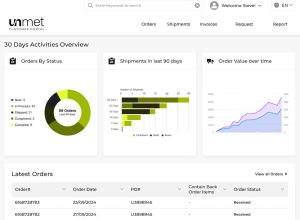

Unmet’s Expertise with Manufacturing Companies

At Unmet, we are helping clients improve this information disconnect with creating the integrations required to share Order, Warranty, Invoice, & Shipping information from the ERP to the CRM so that you can transparently share this information with your customers. What we’ve found is by creating this transparency in a Customer or Partner Portal, it drastically reduces the amount of notification emails, calls to your CSR teams, and generally improves the trust you have with your customers.

We have 10 years of experience working with North American manufacturers to improve their operations and how they build relationships with their customers and partners. Our deep industry knowledge ensures these solutions are perfectly aligned with your manufacturing needs, driving growth and efficiency.